오토의 편의성과 수동의 경제성!

세미오토 전문기업, 핸인핸

Installaion Manual

Installation Manual for Semiauto of Renault Master

The installation manual contents are provided as following sectors.

Process 01.

Installation of motor actuator

Process 02.

Wiring harness

Process 03.

Setting & Adjust the system

Process 04.

Road test and fine adjust

Video for Installation Manual for Semiauto of Renault Master

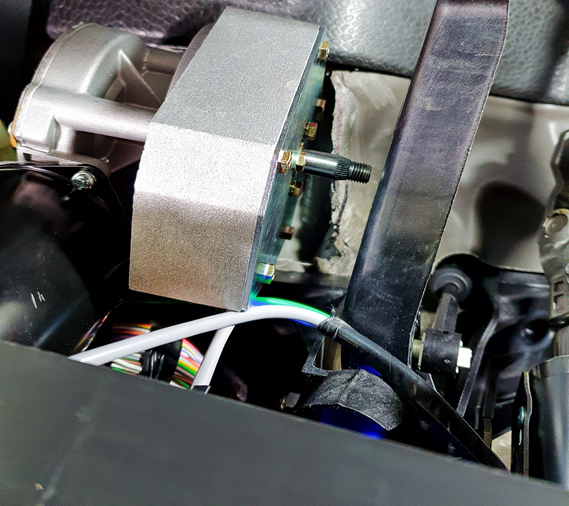

Installation of motor actuator

Before fixing the motor actuator as shown that the clearance of motor shaft and clutch pedal should be departs 5 mm to prevent bstruction when presse the clutch pedal.

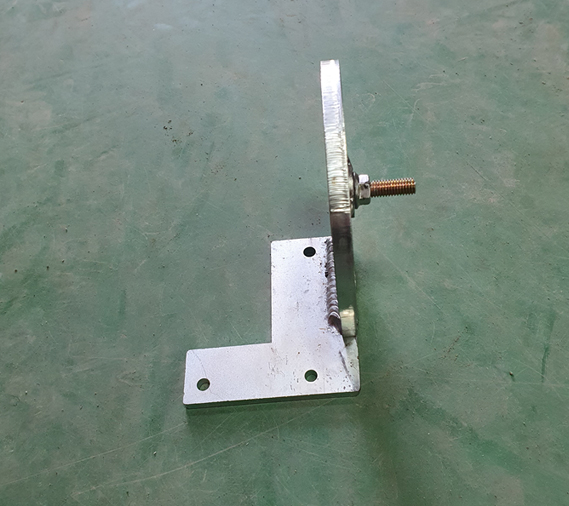

Actuator bracket fixing hole

Cut out the insulation sponge as shown . Use the zig which we supplied to make accurate 8 mm bolt hole.

Use the zig

1. The upper 8 mm hole should be correctly mark and drilled. Use the zig that we supplied.

2. Be sure that the actuator shall be parallel with clutch pedal which about 10 degrees are tilted to left.

3. Use the 6 mm screw bolt for under 2 holes.

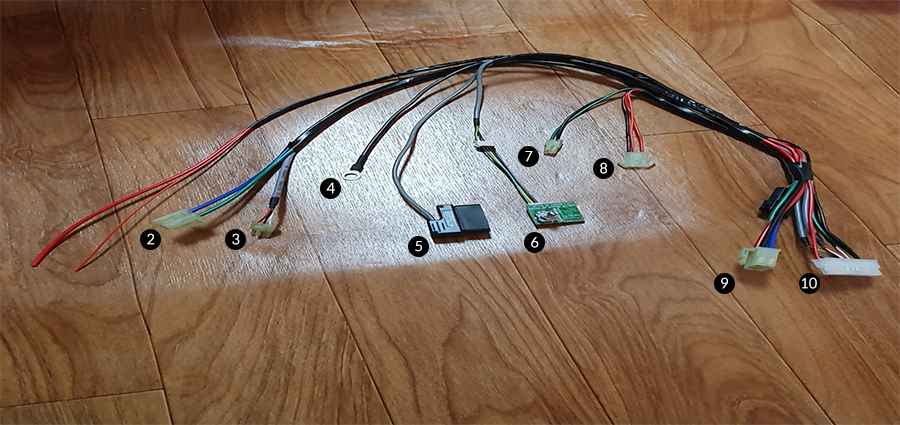

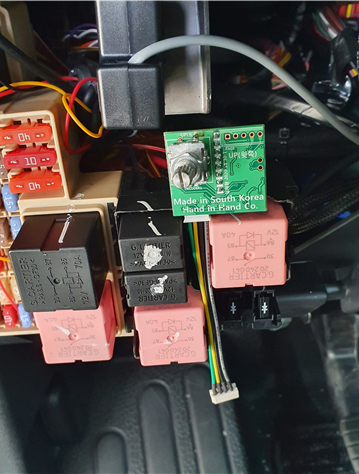

Wiring harness

Described the wiring from left to right of photos. power income of the key assembly.

2. Blue & green : to motor actuator

3. Red & Black & white : CPS of motor.

4. Black wire : ground

5. OBD connector: OBD terminal

6. Slope & Encoder : Should be mount on vertically as shown photo.

7. 2p green & black wire : Hand knob signal.

8. 3p black n 2 red wire : Auto/manual

9. 4p wire: : Main power to motor Thin red : connect to ignition 2 of the key assembly.

10. 20p connector : Signal input terminal.

Connection for each parts

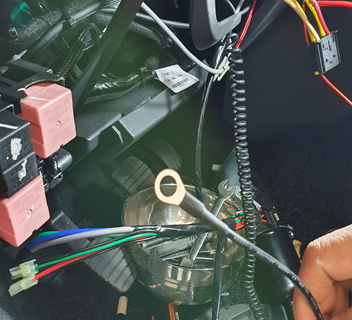

Installation of slope sensor / encoder

Connect the OBD which digital data incomes to ECU

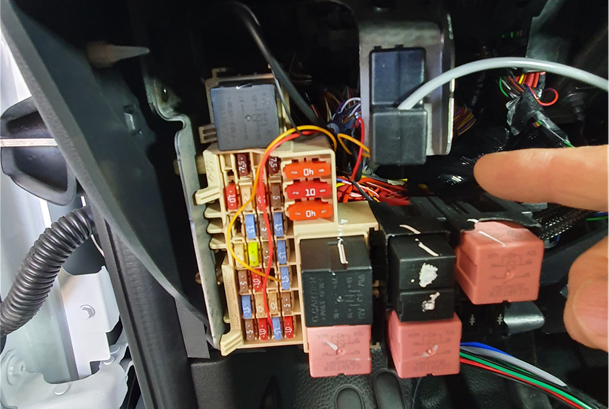

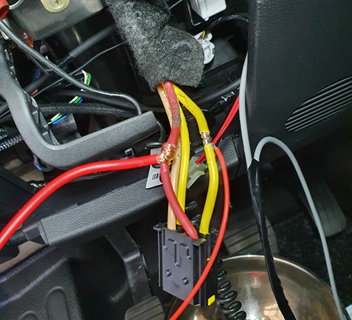

Wiring for main power / IG2 / Ground

Connect the main power supply red of ECU to red wire of key assembly.

01.

Connect the control power supply of ECU to yellow wire (ig-2) of key assembly.

02.

Connect black ground

wire to bolt chassis.

03.

INSTALLATION 1.Auto/manual s.w

Place as shown for auto/manual s.w and Slope sensor/encoder

Be sure that the slope sensor should be positioned vertical 90 degree as shown.

01.

The wire should be downward to plain ground.

02.

Install auto/manuals.w that hole size 22mm.

03.

INSTALL HAND KNOB SWITCH

Be sure that the wire should guide by cable tie to protect chewing when shifting gear shifting to reverse.

Install the hand knob s.w with instant glue as shown and wrap by insulation tape for 30 minutes to hardening. Remove tape after fixed properly.egree as shown.

01.

Guide the wire by cable tie to avoid chewing when shifting the reverse gear position.

02.

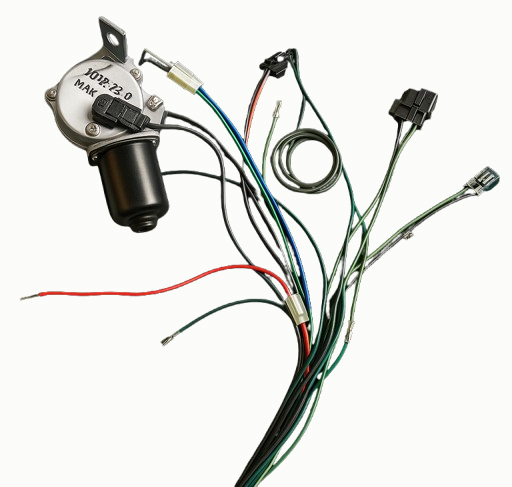

Connect the motor and CPS (Clutch Position Sensor)

Setting the system

After finished installation of the actuator and wiring system, the setting process shall be as followings.

01. Engine start up

02. Power ON mode auto/manual s.w

03. Connect the scanner to USB port of the ECU

04. Power Off mode of auto/manual s.w

05. Install motor actuator arm on the motor shaft

06. Press the hand knob s.w and check the clearance between the clutch pedal and the bottom of the chassi when pressed the clutch pedal and record the CPS value display on the scanner.

07. If the clearance bigger than 5 mm, Press the VR1(-) button of the scanner 5 times shortly , then press hand knob s.w again and check the clearance is 5 mm as described above sentence

Setting process

Record the CPS value that display on the scanner. If the clearance bigger than 5 mm,

✔ Press the VR1(-) button of the scanner 3- 5 times shortly. (Can be press the VR1(-) of ECU)

✔ Press hand knob s.w again and check the clearance will be adjusted is 5 mm as described above sentence 6.

Setting the slope sensor/encoder

✔ Place the vehicle on the flat ground.

✔ Press the slope sensor/encoder about 3 second and try 3-5 times again until the glimmer light steady on the ECU as shown.

Setting the half clutch moving point

✔ Press the hand knob s.w and shift gear position to 1st.

✔ Turn left the slope sensor/encoder display 1.0v higher than VR1 value(value that fully pressed clutch pedal position when pressed hand knob s.w ).

Be sure that brake pedal should pressed when setting or adjust time.

✔ Release the brake pedal and check the starting is smoothly.

✔ If harsh : turn encoder to counter clockwise rotation till smooth starting.

✔ If slow : turn to clockwise till get smooth moving.

Check and test with scanner

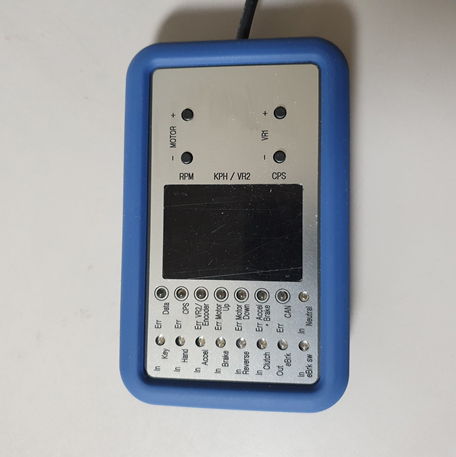

The scanner

1. The scanner displaying every status of the sensor and data.

2. RPM : shows rpm

KPH/VR2 : shows the speed of vehicle when vehicle is moving.

VR2 : shows the half clutch Position that moving the vehicle by voltage when released the brake pedal.

3. CPS : Clutch Position Sensor

4. Motor + and - : Can be test through the motor rotated the clutch pedal moves up and down.

5. VR + and - : Can be set fully pressed position up and down.

6. In : shows every income signal when activated related one.

7. Err : indicating error that related one

Road test